1820 S Grove Avenue | Ontario CA 91761

Being in business for over 25 years has given us the experience we need to know our clientele, polish our in-house processes, and produce high-grade metal die castings that adhere to industry standards.

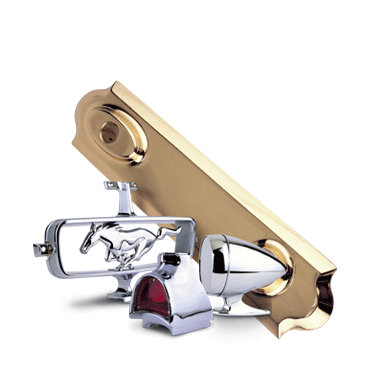

We offer custom die casting services with zinc for clients looking to lower their production costs for high-quality finishes. You may also opt for brass or chrome-plated finishes if you think style and durability are what’s most important.

During our years in business, we have turned to Computer Numerical Control or CNC machining, a process where pre-programmed computer software dictates the movement of machinery. This method makes it easier for us to produce the metal castings and parts needed by our clients to support their operations and supply chains.

CNC machining helps us churn out high-quality and consistent metal parts, which increases our work efficiencies while also decreasing waste. This technology also dramatically reduces the margin of error on physical production and saves all sorts of time and effort in a busy fabricating business.

We have state-of-the-art machines ranging from 250 to 800 tons. These specifically made machines work on various processes, from drilling to plasma cutting; they also create intricate patterns and shapes in metal pieces.

Our team also has experience using two proven methods: cold chamber die casting and hot chamber die casting. Although similar in many ways, they differ mainly in their heating processes. The hot chamber requires the metal to be heated in the machine, whereas the cold chamber requires the metal to be heated in a separate furnace before transferring it to the casting machine.

In hot chamber casting, the raw materials are heated by the furnace. A plunger then forces the metals through a gooseneck line into the die cavity of the mold. The moving half of the mold retracts from the fixed half, while the finished product is removed from the mold by the ejector pins. The mold halves are then made ready for the next batch of molten metal to be injected.

For cold chamber die casting, the raw material is poured from a ladle into the cold chamber. A plunger advances to push the liquid metal into the die cavity. The fixed half remains in place while the moving half of the cavity retracts. Ejector pins in the moving half remove the finished product, and the mold halves are cleaned and made ready for the next production round.

Aside from CNC machining, we provide a full range of turnkey fabricating solutions. Our team has the equipment and tools required to easily accommodate such processes, which include deburring or sanding. We also specialize in completing the entire lifecycle of metal fabrication projects, from the initial build to any required finishing processes.

Our team completes some of the secondary processes to ensure high-quality products, including vibratory deburring, shot blasting, sanding, ball burnishing, impregnating, polishing, powder and wet painting, anodizing, and plating. We also offer complete engineering and tooling support utilizing the latest 3D CAD design software.

We are also known for our complex die casting solutions that adhere to the standards set by the North American Die Casting Association. By strictly following these standards, clients can rest assured that we are a trusted business partner in the manufacturing industry. Our team can provide the customized results you seek for whatever business processes you need to complete.

360, 380, 383, 384, 413, ZA-12, ZA-27

2, 3, 5, 7, ZA-8

We conduct a range of inspection methods that include hand tools, test fixtures, gages, destructive, shot monitoring, and using the Coordinate Measuring Machine. Our team only produces the finest die casting tools with high-grade materials recommended by the North American Die Casting Association. You can check out our past work here!

California Die Casting INC operates a Quality Management System that has certificated compliance with the requirements of ISO 9001:2015.

1820 S Grove Avenue | Ontario CA 91761

© California Die Casting INC. All rights reserved. Website by web.com.